Articles

Learn more about how our products and services help customers just like you on a daily basis.

Sewage treatment focuses on the removal of contaminants from municipal wastewater - the public water system - to produce an effluent that is safe enough to be released into the environment.

At its core, sewage treatment simply aims to speed up the process that sewage undergoes when being purified naturally - how bacteria and other small organisms in water consume the sewage and organic matter and turn it into harmless by-products.

Taking this process, and finding ways to do so in the most time, energy, and cost-efficient way will deliver maximum efficiency for the plant. It also must meet the strict environmental regulations for effluent disposal.

One of the ways this is done best is through aeration. Aeration is the process of adding air to the sewage to promote aerobic biodegradation of the organic contaminants.

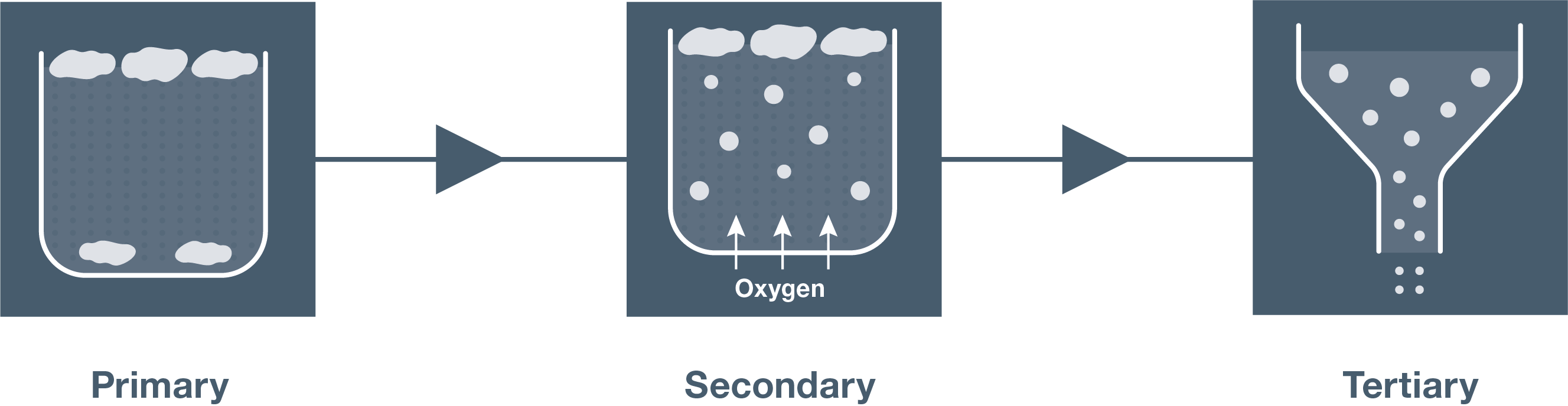

Let’s look at the reasons why sewage needs to be treated and the three main stages of doing so; primary, secondary, and tertiary and see where aeration comes in to play.

It’s simple - sewage left untreated will cause water pollution as well as cut into the ever dissipating freshwater supply. For plants, strict regulations are placed on wastewater outputs so they must adhere or face penalties.

It also makes sense to utilise as much of the water they consume as possible, before disposing of it. Many companies are finding new ways to optimise their wastewater outputs through innovative processes- Read more about how Industries Are Treating Their Wastewater With Zero Liquid Discharge.

So the goal of sewage treatment for plants is to reduce the contaminants within it so that it meets the environmental regulations for disposal, doing so in the most energy efficient manner.

In terms of sewage this may mean going through several stages of treatment - pretreatment, primary treatment, secondary treatment, and potentially an additional tertiary treatment stage may be required.

First things first, sometimes the wastewater may require a pre-treatment stage to remove any bulky materials that can be easily collected such as trash, branches and any other large objects that might have fallen into the stream from storm or urban runoffs. This stage of sewage treatment often includes the physical processes of screening and grit removal.

Screening is the physical method of placing long, closely spaced, narrow metal bars which block any floating debris that could potentially clog pipes or pumps. The debris can then be removed by hand or by a mechanically operated rake.

Grit chambers are long narrow tanks that are designed to slow down the wastewater flow so that solids such as sand and gravel can settle to the bottom where they will be removed. Even at this early stage aeration can be used to optimise this process.

In aerated grit chambers aeration supplied by blowers is introduced creating a circular flow pattern in the wastewater helping the grit settle to the bottom of the chamber while keeping the remaining material in suspension.

Using aeration here means that grit is more efficiently removed, reducing any problems that grit can cause in the processes further downstream. Selected blowers will deliver maximum efficiency - check out our selection of blowers here.

Note, mechanical surface-skimming devices are also used to remove grease and other floating materials before primary treatment begins. This is where sewage treatment really begins.

The sewage now has less physical objects and potentially troublesome grit in it, but there is still both organic and inorganic material that remains and needs to be removed.

The primary stage is where any organic or non-organic material that either floats or settles out via gravity is removed. This often takes place in sedimentation tanks and the process is called sedimentation.

Sedimentation tanks, also called primary clarifiers, are used to let the suspended solids that pass through the screens and grit chambers more time to settle and sink.

The settled solids, now called sludge, will be moved along the bottom of the tank by mechanical scrapers. The sludge is then collected in a hopper at the base of the tank and pumped out for further sediment treatment.

The remaining sewage wastewater will now move along to receive its further treatments of purification to meet the desired effluent levels for disposal or reuse.

Secondary treatment is now used to substantially break down the remaining organic matter of the sewage using aerobic biological processes.

The biological processes make use of the bacteria found in the sewage in the same way as how it would work in nature, just with an extra hand to move things along - aeration. Aeration is the process of adding air into wastewater to allow aerobic biodegradation of the organic materials.

The principal secondary treatment techniques used are the trickling filter and the activated sludge process and are often classified as fixed-film or suspended-growth systems respectively.

The fixed-film systems include trickling filters, constructed wetlands, and rotating biological contractors. In these systems, the bacteria grow on media, such as stones or reeds, and as the sewage passes over it the bacteria get to work consuming the organic matter. Adding oxygen will stimulate the activity of the bacteria. The resulting ‘purified’ water trickles out through pipes for further treatment.

Suspended-growth systems include the activated sludge process. This is where the sewage gets pumped into an aeration tank, where it is mixed with air and sludge loaded with bacteria. It is then allowed to remain for several hours, during this time the bacteria break down the organic matter into harmless by-products. The sludge, now activated with additional billions of bacteria and other tiny organisms, can be used again by returning it to the aeration tank for mixing with air and new sewage.

The partially treated effluent then flows to another sedimentation tank for removal of excess bacteria. To be effective these processes must have an ample and evenly distributed supply of air.

Without the presence of sufficient oxygen, bacteria will not be able to breakdown the incoming organic matter in a reasonable time. Not only will the process be slow but it will result in septic conditions that can become toxic and result in far less efficient contaminant removal.

A well-designed aeration system has a direct impact on the efficiency of the wastewater treatment. Reducing the length the process takes, increasing energy efficiency, and cutting costs.

With aeration accounting for over 60% of power requirements, it is essential to make sure you get an efficient solution.

Nowadays with higher populations, varying uses of water, and a greater volume of contaminants found, sewage treatment often requires further treatment to be certain that the effluent will cause no harm to the environment on release.

There is an advanced range of physical, chemical, and biological processes that are used to do just this. And depending on what the main characteristics of the sewage are, and what contaminants it contains, the wastewater might require only a few of these treatments, or maybe several combined, to be deemed safe enough for disposal.

Tertiary wastewater treatment is often used to tackle the more difficult contaminants such as heavy metals, chemical compounds, and toxic substances.

Advanced waste treatment techniques range from biological treatment capable of removing nitrogen and phosphorus to physical-chemical separation techniques such filtration, carbon adsorption, distillation, and reverse osmosis.

Sewage treatment processes, alone or in combination, can achieve an amazing degree of water purification, so much so that the effluent can even be reused for industrial, agricultural, or recreational purposes - or even drinking water.

During wastewater treatment over 60% of power requirements go towards aeration.

And as aeration is central to the level of efficiency in processing wastewater for disposal it is essential that you have the technology and equipment to meet these demands