Waste-To-Energy

Waste-to-Energy plays an important role in responsibly managing waste and generating renewable non-fossil fuel energy, Howden steam turbines, fans and heaters enable efficient operation throughout.

Howden products are proven throughout the power generation industry from large traditional plants to smaller output plants fuelled by municipal waste and biomass. Each piece of equipment is designed to maximise efficient performance and provide reliable operation.

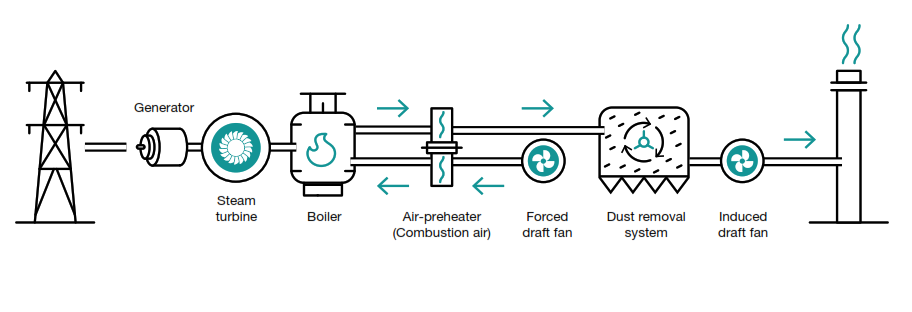

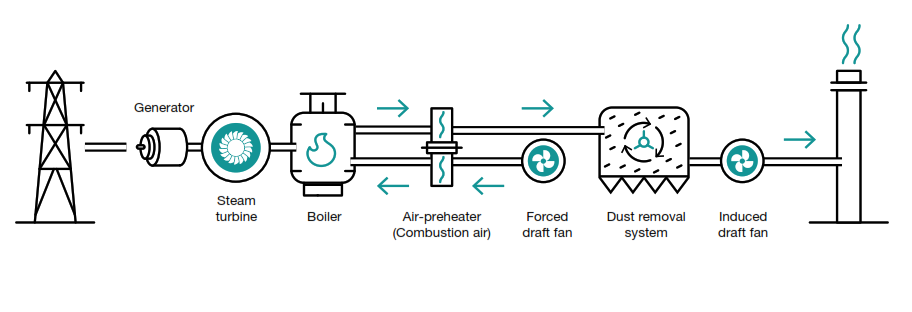

Whether it is fuelled by municipal waste (MSW) or biomass, a waste-to-energy power plant uses a combustion process to raise steam for a steam turbine generator.

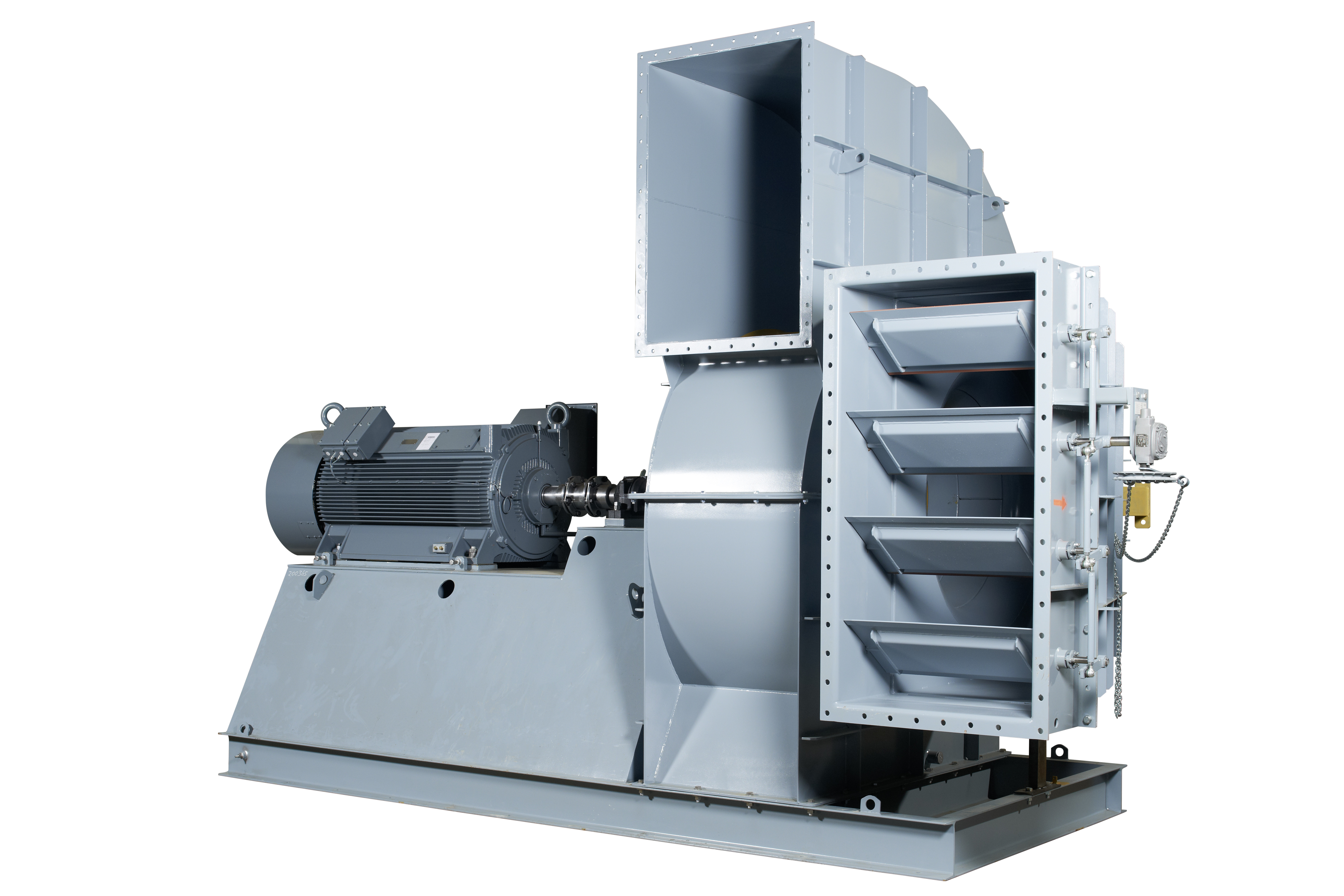

Howden equipment plays an important role in the combustion process. Centrifugal fans are deployed as Forced Draught (FD) fans to supply fresh air for the combustion of waste materials, and as Induced Draught (ID) fans to draw the flue gases through a dust collection system.

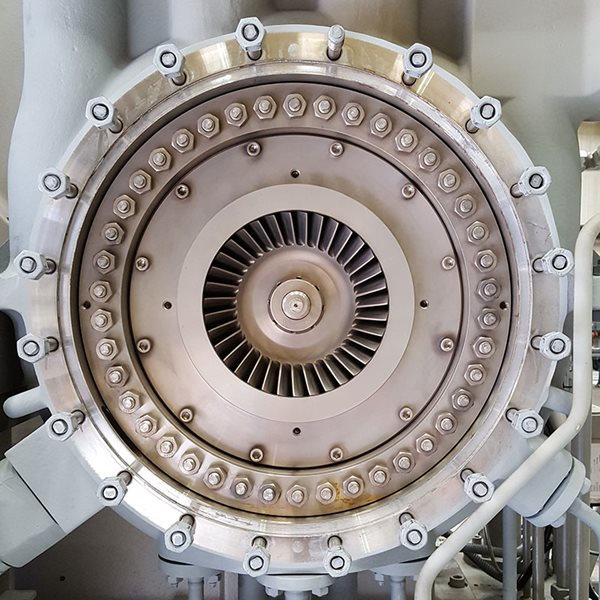

The steam generated in the boiler can be used as process steam for district heating or to drive a steam turbine for the production of electricity. Howden legacy steam turbine brands (Kühnle, Kopp & Kausch and Peter Brotherhood) are renowned for handling load variations, and thus switching between the different outputs.

The combustion process can be made more efficient through preheating the combustion air. To do this, Howden supply regenerative rotary air preheaters, which slowly rotate at around 1-2 rpm, absorbing heat from the hot gas stream in thin metal heat transfer elements and transferring it to the incoming cold air stream.

Typical processes servedWhether it is fuelled by municipal waste (MSW) or biomass, a waste-to-energy power plant uses a combustion process to raise steam for a steam turbine generator.

Howden equipment plays an important role in the combustion process. Our centrifugal fans are deployed as Forced Draught (FD) fans to supply fresh air for the combustion of waste materials, and as Induced Draught (ID) fans to draw the flue gases through a dust collection system.

The steam generated in the boiler can be used as process steam for district heating or to drive a steam turbine for the production of electricity. Howden steam turbine brands (Kühnle, Kopp & Kausch and Peter Brotherhood) are renowned for handling load variations, and thus switching between the different outputs.

The combustion process can be made more efficient through preheating the combustion air. To do this, Howden supply regenerative rotary air preheaters, which slowly rotate at around 1-2 rpm, absorbing heat from the hot gas stream in thin metal heat transfer elements and transferring it to the incoming cold air stream.

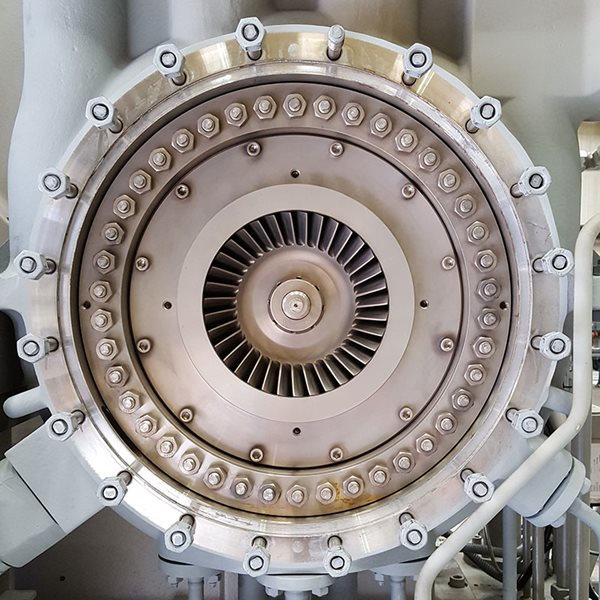

Typical processes servedBased on the heritage of Kühnle, Kopp & Kausch and Peter Brotherhood, Howden can meet the need for standard configurable steam turbines to fully custom-engineered solutions. Our steam turbines deliver over 1000 MW of installed power in Waste-to-Energy Power Plants globally. They are used extensively with small-scale industrial power, waste heat recovery and renewable energy systems

Project examplesWaste comes in many forms, with our turbines fed from steam generated by the incineration of municipal waste, waste steam from industrial processes and wood biomass. One of our customers, a sawmill, uses our steam turbine to generate 24MW of electrical power, while another incinerates sewage sludge for 3.3MW of energy recovery.

Our turbines are used to support agricultural waste to energy such as one customer in Spain using olive waste for a 8MW turbine. This turbine provides steam for the facility as well as electrical output to the grid. Another customer incinerates Meat and Meal Bone (MBM) to generate 14MW of electrical power, which supplies local industry and homes.

The sugar industry is also a large producer of energy from waste materials. The 'bagasse' (sugar cane waste material) is burned to raise steam for process needs as well as electrical output. We have supplied over 500 steam turbines to this particular segment.

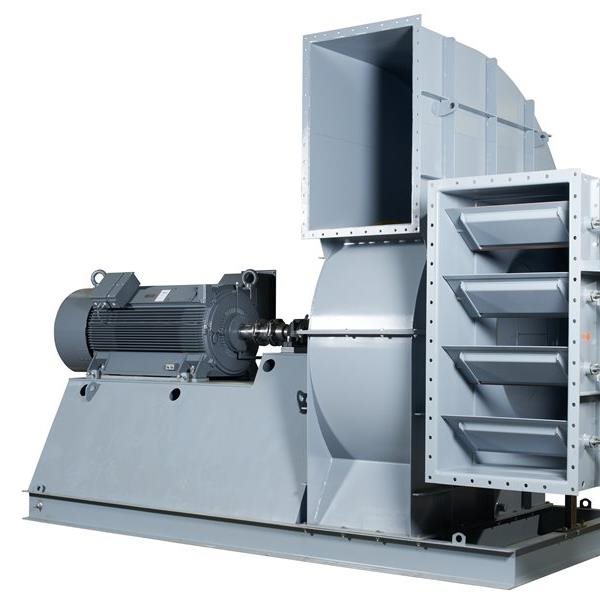

Our fans range from configured to fully engineered to meet a wide variety of customer demands. Our engineering capability means we can have the knowledge, experience and ability to adapt and develop new designs for specific requirements.

All fans are designed to maximize efficient operation with some reaching over 90% depending on application and operation.

Regenerative air preheaters aim to increase the efficiency of the boiler by 10-15%.

The package air preheater product range provides operators looking to recover energy from fired equipment a highly efficient, low maintenance solution in a compact footprint. It can handle flue gas flows of under 50 tonnes per hour to around 200 tonnes per hour and recovered energy can extend to over 15MW depending on gas temperature drop.

The heaters are suitable for integration into new plant development as well as replacements of alternative technologies within operational sites. All heaters are fully supported by Howden’s global pre-sales and aftermarket capabilities to ensure ease of project engineering and reliable long-term performance.

Howden has a wide range of fans to meet performance requirements and deliver outstanding performance in efficiency and noise levels, regardless of cooling plant design.

Our fans can operate in cooling towers, air cooled condensers and air cooled heat exchangers with a low pressure drop of up to 250 Pa and high air flow volume of up to 3000 m3/s.

Twence waste-to-energy plant in the Netherlands needed to increase the performance and output of the turbine during the hot summer periods. This can be achieved by increasing the water-steam cycle efficiency through increase of the turbine backpressure. A precondition was to keep the noise emission at the same level due to local regulations.

Increasing the airflow through their Air-Cooled Condensers (ACC) was necessary and achievable by increasing the speed of the existing fans, but the consequence of increased speed is also an increase of noise level. For this reason the Howden SXT, an ultra-low noise fan was selected as it delivers more airflow while running at a lower speed. The SXT fan also fits the existing fan ring giving considerable savings with regards to installation time and capex.

10 SXT fans were installed, increasing the airflow per fan by ~29%. This has resulted in about 10.5% more power output from the plant at the same ambient temperature and steam flow.

The plant went further by installing Howden Uptime (our condition monitoring system) to reduce unplanned maintenance on their cooling fans, resulting in higher efficiency and productivity.

Howden’s aftermarket services consistently minimise costs and downtime whilst improving the performance of your operations. Collaborating with us is key to continuous, efficient equipment performance with minimum downtime over its lifetime.

Maintenance & repairsFor waste to energy plants, we offer a complete aftermarket solution that covers the entire process, ranging from axial fans, centrifugal fans, cooling fans, compressors, heaters and electrostatic precipitators to steam turbines, gearboxes and generators.

Howden’s maintenance philosophy is based on minimising the total cost of ownership by determining the most efficient balance between availability and reliability. We safeguard reliability by fully investigating any failures that occur, and preventing their recurrence. Our engineering experience and the feedback we receive allows us to continually improve our maintenance strategies and plans, which have evolved into a comprehensive and flexible modular system designed to actively optimise the performance of your plant.

Spare partsHowden supplies genuine OEM spare parts that are made to the same high performance standards as our products. This means that each part will fit perfectly and maintain the high quality standards your process equipment needs to operate reliably and efficiently.

Steam Turbine-Generator ServicesBy leveraging the capabilities of our subsidiary Maintenance Partners, we offer services, spare parts and upgrades of steam turbines, gearboxes and generators of any brand.

Howden Uptime is a unique digital solution that gathers the physical sensor data from any kind of rotating equipment and analyses how it operates and responds to the environment.

This solution is designed to provide invaluable insight into asset performance, that can increase the availability of the equipment while significantly reducing costs. Howden Uptime brings the following benefits:

Based on the heritage of Kühnle, Kopp & Kausch and Peter Brotherhood, Howden can meet the need for standard configurable steam turbines to fully custom-engineered solutions. Our steam turbines deliver over 1000MW of installed power in Waste-to-Energy Power Plants globally. They are used extensively with small-scale industrial power, waste heat recovery and renewable energy systems

Project examplesWaste comes in many forms, with our turbines fed from steam generated by the incineration of municipal waste, waste steam from industrial processes and wood biomass. One of our customers, a sawmill, uses our steam turbine to generate 24MW of electrical power, while another incinerates sewage sludge for 3.3MW of energy recovery.

Our turbines are used to support agricultural waste to energy, such as one customer in Spain, using olive waste for a 8MW turbine. This turbine provides steam for the facility as well as electrical output to the grid. Another customer incinerates Meat and Meal Bone (MBM) to generate 14MW of electrical power which supplies local industry and homes.

The sugar industry is also a large producer of energy from waste materials. The 'bagasse' (sugar cane waste material) is burned to raise steam for process needs as well as electrical output. We have supplied over 500 steam turbines to this particular segment.

Our fans range from configured to fully engineered to meet a wide variety of customer demands. Our engineering capability means we can have the knowledge, experience and ability to adapt and develop new designs for specific requirements.

All fans are designed to maximize efficient operation with some reaching over 90% depending on application and operation.

Regenerative air preheaters aim to increase the efficiency of the boiler by 10-15%.

The package air preheater product range provides operators looking to recover energy from fired equipment a highly efficient, low maintenance solution in a compact footprint. It can handle flue gas flows of under 50 tonnes per hour to around 200 tonnes per hour and recovered energy can extend to over 15MW depending on gas temperature drop.

The heaters are suitable for integration into new plant development as well as replacements of alternative technologies within operational sites. All heaters are fully supported by Howden’s global pre-sales and aftermarket capabilities to ensure ease of project engineering and reliable long-term performance.

Howden has a wide range of fans to meet performance requirements and deliver outstanding performance in efficiency and noise levels, regardless of cooling plant design.

Our fans can operate in cooling towers, air cooled condensers and air cooled heat exchangers with a low pressure drop of up to 250 Pa and high air flow volume of up to 3000 m3/s.

Reference projectTwence waste-to-energy plant in the Netherlands needed to increase the performance and output of the turbine during the hot summer periods. This can be achieved by increasing the water-steam cycle efficiency through increase of the turbine backpressure. A precondition was to keep the noise emission at the same level due to local regulations.

Increasing the airflow through their Air-Cooled Condensers (ACC) was necessary and achievable by increasing the speed of the existing fans, but the consequence of increased speed is also an increase of noise level. For this reason the Howden SXT, an ultra-low noise fan was selected as it delivers more airflow while running at a lower speed. The SXT fan also fits the existing fan ring giving considerable savings with regards to installation time and capex.

10 SXT fans were installed, increasing the airflow per fan by ~29%. This has resulted in about 10.5% more power output from the plant at the same ambient temperature and steam flow.

The plant went further by installing Howden Uptime (our condition monitoring system) to reduce unplanned maintenance on their cooling fans, resulting in higher efficiency and productivity.

Howden’s aftermarket services consistently minimise costs and downtime whilst improving the performance of your operations. Collaborating with us is key to continuous, efficient equipment performance with minimum downtime over its lifetime.

Maintenance & repairsFor waste to energy plants, we offer a complete aftermarket solution that covers the entire process, ranging from axial fans, centrifugal fans, cooling fans, compressors, heaters and electrostatic precipitators to steam turbines, gearboxes and generators.

Howden’s maintenance philosophy is based on minimising the total cost of ownership by determining the most efficient balance between availability and reliability. We safeguard reliability by fully investigating any failures that occur, and preventing their recurrence. Our engineering experience and the feedback we receive allows us to continually improve our maintenance strategies and plans, which have evolved into a comprehensive and flexible modular system designed to actively optimise the performance of your plant.

Spare partsHowden supplies genuine OEM spare parts that are made to the same high performance standards as our products. This means that each part will fit perfectly and maintain the high quality standards your process equipment needs to operate reliably and efficiently.

Steam Turbine-Generator ServicesBy leveraging the capabilities of our subsidiary Maintenance Partners, we offer services, spare parts and upgrades of steam turbines, gearboxes and generators of any brand.

Howden Uptime is a unique digital solution that gathers the physical sensor data from any kind of rotating equipment and analyses how it operates and responds to the environment.

This solution is designed to provide invaluable insight into asset performance, that can increase the availability of the equipment while significantly reducing costs. Howden Uptime brings the following benefits:

Telephone +44 141 885 7500