Helium Liquefiers

Helium liquefaction capacities from 50 to 600 million standard cubic feet per year (mmscfy).

Cryo Technologies’ vacuum cold box engineering, design and fabrication expertise affords us the ability to offer our customers helium liquefiers of unparalleled performance and quality. Our full range of engineering and design competencies include process, mechanical, instrumentation, controls, safety, procurement, quality assurance, project management and 3D modeling.

A warm, pure helium feed stream is compressed (if required) to achieve the liquefier high pressure stream design pressure. The pure, high pressure helium feed stream enters a vacuum cold box where it is cooled by liquid nitrogen and recycle refrigeration. Recycle refrigeration is provided by compressing a separate helium recycle stream and expanding it in one or more turboexpanders. The refrigerated helium feed stream is then expanded in a reciprocating expansion engine to produce a two-phase helium stream. The two-phase stream flows into a storage tank where the liquid and vapor are separated. The liquid helium remains in the storage tank and the cold helium vapor is returned to the cold box where it is used to cool the helium feed stream. A complete liquefaction system typically includes recycle and feed (where applicable) compressors, oil removal systems, a vacuum cold box containing heat exchangers, 80K & 20K adsorbers, turboexpanders and reciprocating expander(s), valves & instruments, product storage, distribution & trailer loading systems and control & analytical systems.

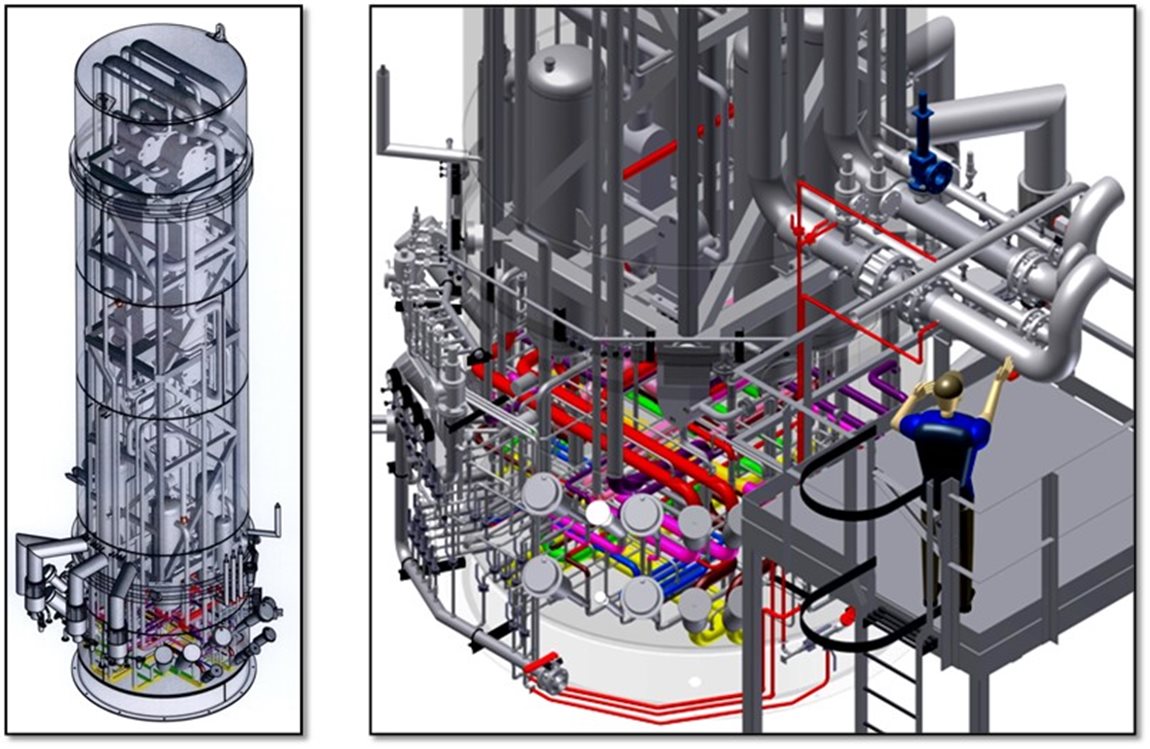

2300 L/Hr Helium Liquefier Vacuum Cold Box – 3D Inventor Model – 10 ft Diameter x 40 ft High x 75,000 lb

The combination of Chart and Cryo Technologies offers the market a unique one-stop shop for customers who want to liquefy, store, distribute and market liquid helium, regardless of plant capacity.

Chart's helium liquefaction processes use liquid nitrogen pre-cooling, helium recycle refrigeration and rotating equipment, all designed and selected to offer our customers the optimum balance between CAPEX and OPEX.

Proven process technologies, high quality, custom engineered and commercially available components, expert fabrication and maximized shop packaging unite to reduce cost, schedule, and risk.

To meet each customer’s specific needs. customization options include choice of capacity, optional front-end purification, optional nitrogen re-liquefaction, and unlimited storage and trailer loading options.

With >20 years specialty cryogenic engineering and welding expertise, the acquisition of Fronti brings another cryogenic industry partner into the Chart portfolio, expands our cold box manufacturing capability and capacity, including hydrogen and helium liquefiers and creates the foundation for our mid-Atlantic flexible manufacturing location.

View and download literature

Cryo Technologies Main Office +1 610 530 7288