Tunnel Ventilation

Howden ensures the provision of air through critical ventilation systems, providing a safe environment for both travelers and transport workers within underground transport systems.

Howden has developed its solution approach to all tunnelling projects from road to rail to ensure industry-leading performance you can rely on. Our expertise starts at concept enabling the optimisation of system design and continues throughout the lifetime of operation using leading modelling, fan and digital technology to deliver a truly end-to-end solution.

For underground infrastructure, safety is critical for operation. This means that all ventilation equipment and systems need to meet the highest of standards.

Within tunnels, Howden's fans provide both ventilation through air supply and extraction of air pollutants and emergency smoke extraction in the event of fire.

The ventilation system will differ based on scale and particular requirements of each tunnel. Howden serves longitudinal and transverse systems using our wide range of jet and axial fans.

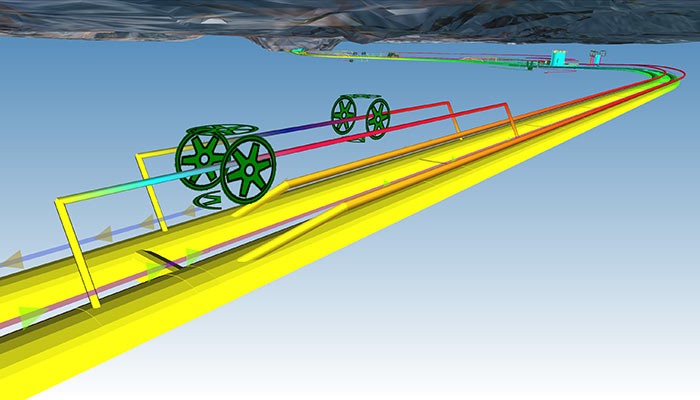

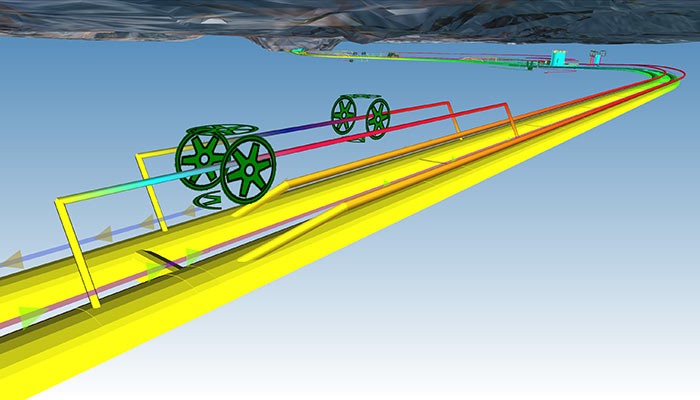

In longitudinal tunnel ventilation systems, jet fans are typically installed within the tunnel to drive ventilation air through the tunnel by impulse transmission. Whereas for transverse systems, ventilation air is delivered into the tunnel at intervals throughout its length by large axial fans situated in ventilation stations above ground with ducting to distribute the air.

In some cases, ventilation and smoke extraction functions are separated to optimise performance efficiency for the continuous use ventilation fans. The large diversity of the Howden fan range means we are capable of answering every challenge.

Learn more about ventilation solutions for infrastructure tunnels in our short videoFor underground infrastructure, safety is critical for operation. This means that all ventilation equipment and systems need to meet the highest of standards.

Within tunnels, Howden's fans provide both ventilation through air supply and extraction of air pollutants and emergency smoke extraction in the event of fire.

The ventilation system will differ based on scale and particular requirements of each tunnel. Howden serves longitudinal and transverse systems using our wide range of jet and axial fans.

In longitudinal tunnel ventilation systems, jet fans are typically installed within the tunnel to drive ventilation air through the tunnel by impulse transmission. Whereas for transverse systems, ventilation air is delivered into the tunnel at intervals throughout its length by large axial fans situated in ventilation stations above ground with ducting to distribute the air.

In some cases, ventilation and smoke extraction functions are separated to optimise performance efficiency for the continuous use ventilation fans. The large diversity of the Howden fan range means we are capable of answering every challenge.

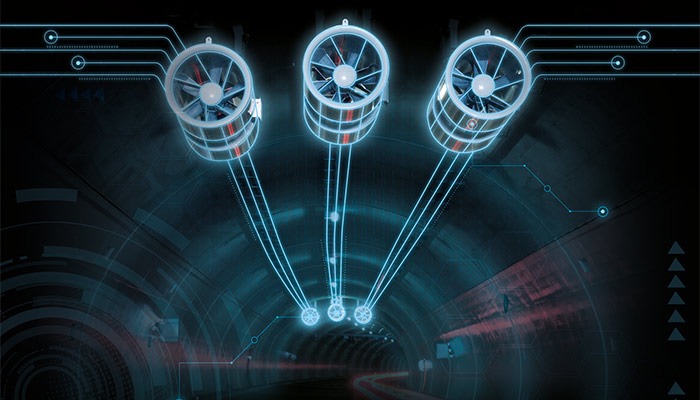

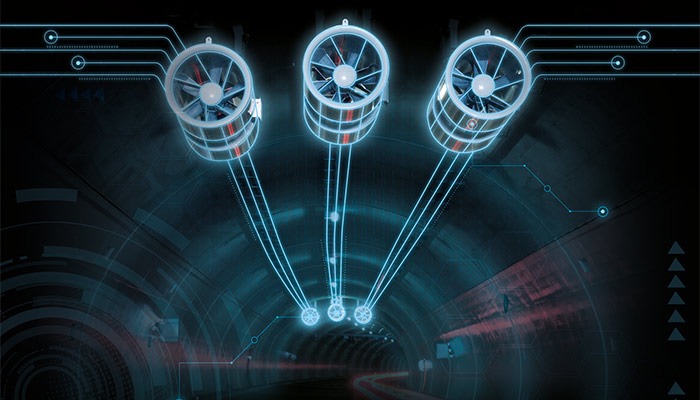

Learn more about ventilation solutions for infrastructure tunnels in our short videoHowden’s range of axial fans for tunnel ventilation has been developed and improved thanks to many years’ experience in the market with multiple brands.

Our axial fans cover a wide range of performance duties and can be configured as reversible or uni-directional to suit the needs of all tunnel ventilation systems.

Every fan is designed and manufactured to the highest quality standards for assurance of safe and reliable operation in the event of fires and long-term performance. Fans are tested to the most stringent fire safety standards (DIN EN 12101-3 or ISO 27927) to operate at 200ºC/1h or up to 400ºC/2h. Aerodynamic testing of fans ensures performance meets or exceeds all required standards demanded by project specifications.

Our fans can be delivered on a scalable basis including full turnkey and are backed up by a comprehensive aftermarket capability to ensure performance is maximised throughout the life of each operation.

Jet fans are the selection of choice for longitudinal ventilation systems in tunnels with single or bi-directional traffic.

Our jet fans provide high thrust relative to power to deliver air efficiently through the tunnel.

Ventsim™ Tunnel DESIGN addresses all aspects of road tunnel airflow management and emergency smoke extraction, while providing actionable insight and output to engineers working on tunnel ventilation.

Ventsim enables rapid development and testing of ventilation models:

Digitalisation is improving the way many industries control and optimize their assets. This is also true in transportation tunnels and Howden is a leader in the field.

Fans are fitted with multiple sensors allowing our Howden Uptime platform to seamlessly integrate related performance data. The system combines active inputs, such as temperature, pressure and vibration, with reference parameters from manuals, specifications and maintenance reports. When the data is analysed, it provides a unique foundation for maintaining and enhancing operational excellence.

A ventilation system must operate reliable for multiple decades. Keeping fans well maintained and rated for conditions is critical, as some fans operate on a continuous basis and other fans need to respond instantly to emergencies.

Howden offers full lifetime service coverage. We have a permanent presence across every continent with specialist engineers able to ensure reliable performance through expert maintenance and quick resolutions to any unexpected issues.

The range of services on offer support our ventilation equipment as well as fans supplied by other manufacturers.

Our range of services includes:

Services are delivered either on-site or in our workshops depending on the nature of the service and customer requirement.

Howden’s range of axial fans for tunnel ventilation has been developed and improved thanks to many years’ experience in the market with multiple brands.

Our axial fans cover a wide range of performance duties and can be configured as reversible or uni-directional to suit the needs of all tunnel ventilation systems.

Every fan is designed and manufactured to the highest quality standards for assurance of safe and reliable operation in the event of fires and long-term performance. Fans are tested to the most stringent fire safety standards (DIN EN 12101-3 or ISO 27927) to operate at 200ºC/1h or up to 400ºC/2h. Aerodynamic testing of fans ensures performance meets or exceeds all required standards demanded by project specifications.

Our fans can be delivered on a scalable basis including full turnkey and are backed up by a comprehensive aftermarket capability to ensure performance is maximised throughout the life of each operation.

Jet fans are the selection of choice for longitudinal ventilation systems in tunnels with single or bi-directional traffic.

Our jet fans provide high thrust relative to power to deliver air efficiently through the tunnel.

Ventsim Tunnel DESIGN addresses all aspects of road tunnel airflow management and emergency smoke extraction, while providing actionable insight and output to engineers working on tunnel ventilation.

Ventsim enables rapid development and testing of ventilation models:

Digitalisation is improving the way many industries control and optimize their assets. This is also true in transportation tunnels and Howden is a leader in the field.

Fans are fitted with multiple sensors allowing our Howden Uptime platform to seamlessly integrate related performance data. The system combines active inputs, such as temperature, pressure and vibration, with reference parameters from manuals, specifications and maintenance reports. When the data is analysed, it provides a unique foundation for maintaining and enhancing operational excellence.

A ventilation system must operate reliable for multiple decades. Keeping fans well maintained and rated for conditions is critical, as some fans operate on a continuous basis and other fans need to respond instantly to emergencies.

Howden offers full lifetime service coverage. We have a permanent presence across every continent with specialist engineers able to ensure reliable performance through expert maintenance and quick resolutions to any unexpected issues.

The range of services on offer support our ventilation equipment as well as fans supplied by other manufacturers.

Our range of services includes:

Services are delivered either on-site or in our workshops depending on the nature of the service and customer requirement.

Australia +61 3924 88625

China +86 1066 419988

Europe & Middle East +49 732 155 04918

India +91 4426 793585

North America +1 513 714 7039

South America +55 11 4487 6250