Glass

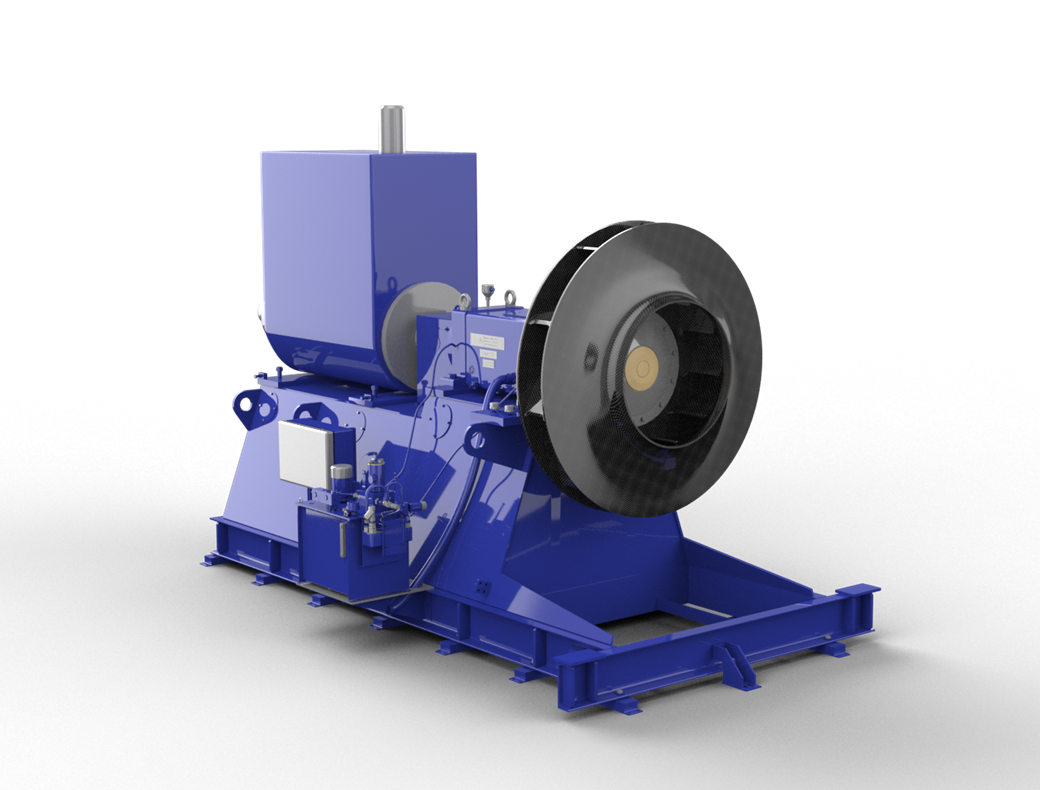

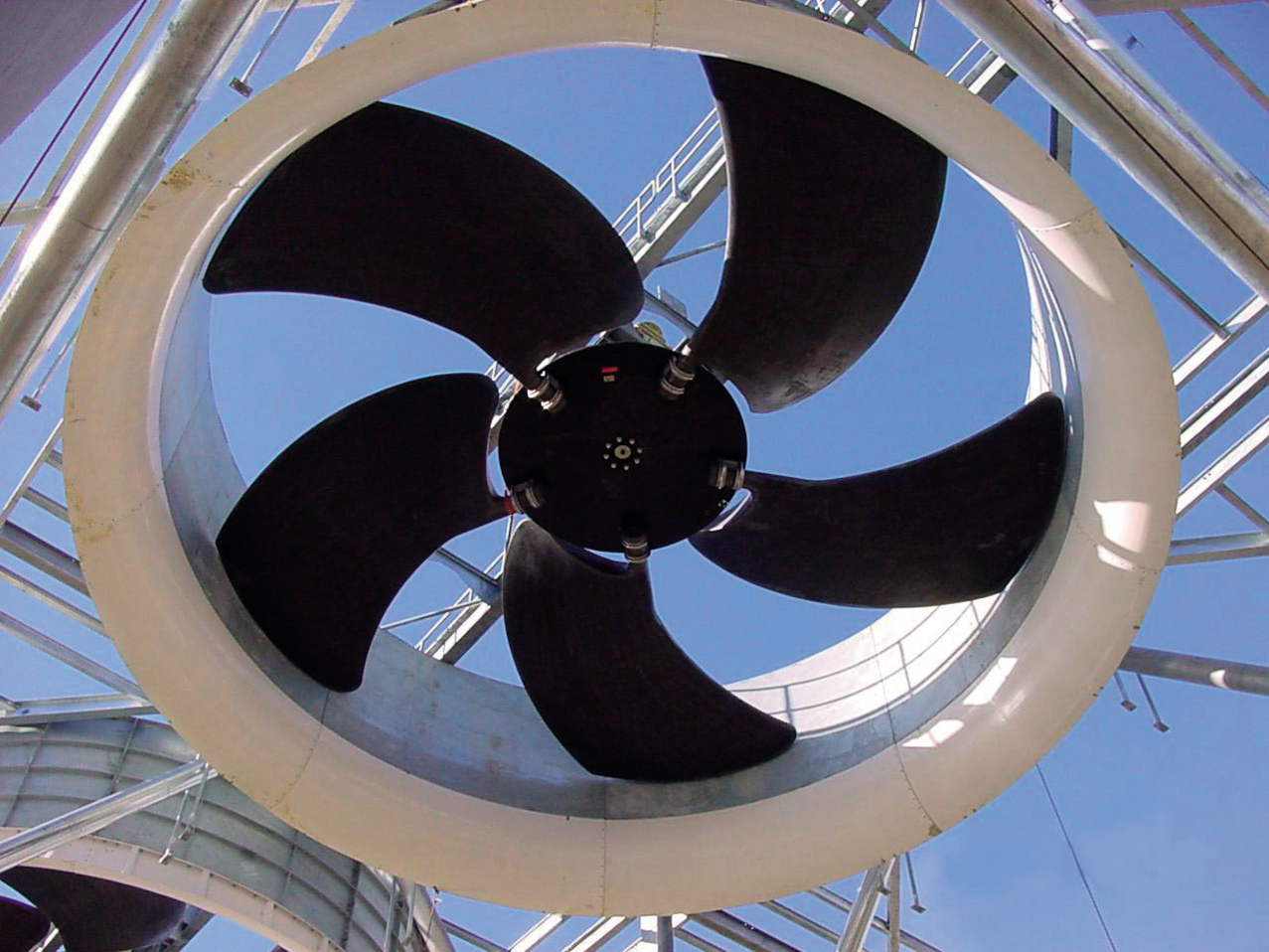

Our products are found throughout the glass production process wherever there is a need for air and other industrial gases. Energy recovery, carbon capture and water treatment solutions further enable plant owners to operate their facilities more efficiently and sustainably .

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team